The future of hospital design – delivering adaptability

As part of our series of articles looking at Buro Happold’s Hospital of the Future project, we examine how future hospital facilities will need to be able to continually adapt to changing circumstances.

Step forward twenty years, and it’s easy to imagine a very different world. Our way of life is likely to have changed significantly in response to the impact of developing technologies, evolving demographic shifts, and in our response to the shocks and stresses facing daily life, not least in our requirement to adapt to climate change.

But one key group of facilities in our cities that have not undergone a major conceptual design change in the last century, are our hospitals. What should the hospital of the future be? Should it be merely an improvement on existing models, or should we be making a fresh start and completely rethink hospital design for the healthcare needs of tomorrow?

Buro Happold, with OMA and other collaborators, was commissioned to explore this question by leading healthcare providers in the Middle East.

We have been working on this extensive research project in parallel with a healthcare district masterplan. Running these workstreams together has given us the rare opportunity to explore a step change in the evolution of the hospital. A key achievement has been the development of a prototype for the Hospital of the Future.

The report presents the design of a prototype that seeks to address the problems that hospitals are facing today. It considers, from the first principles of design, how future hospitals may be redefined.

Future hospital design – engineered to be agile

Our research identified the importance of adaptability and agility for the Hospital of the Future. These principles have been embedded into the design of the prototype, along with elevated levels of resiliency to allow the hospital to ride out shock events.

As well as permitting adaptation, the modular nature of the prototype permits the gradual expansion and contraction, without impacting on the operations and critical function of the live hospital itself.

Sallyanne Lewis, associate director in the structures team at Buro Happold, says: “We have tried to think beyond what happens in a hospital now, to what may be happening in the future. It’s about trying to imagine something that doesn’t exist yet. But to do that, you have to clearly understand the demands on the current hospitals and on healthcare generally. You need to see where the stretch is on those demands and look at where they may go in the future.”

The report outlines a series of key drivers for change, including the acknowledgement that the healthcare needs of a population are not static; and that the innovations in healthcare provision are accelerating as technology evolves. Many functions that were previously performed in hospitals can now be undertaken remotely.

The prototype seeks to tackle these particular challenges to the design of hospital buildings by providing a super-adaptive model for the Hospital of the Future.

Modular hospital construction – built-in adaptability

Conceived as a Modernist “machine”, the structure and services within the hospital of today are highly rigid and hard to adapt. The Hospital of the Future will be designed to avoid early obsolescence.

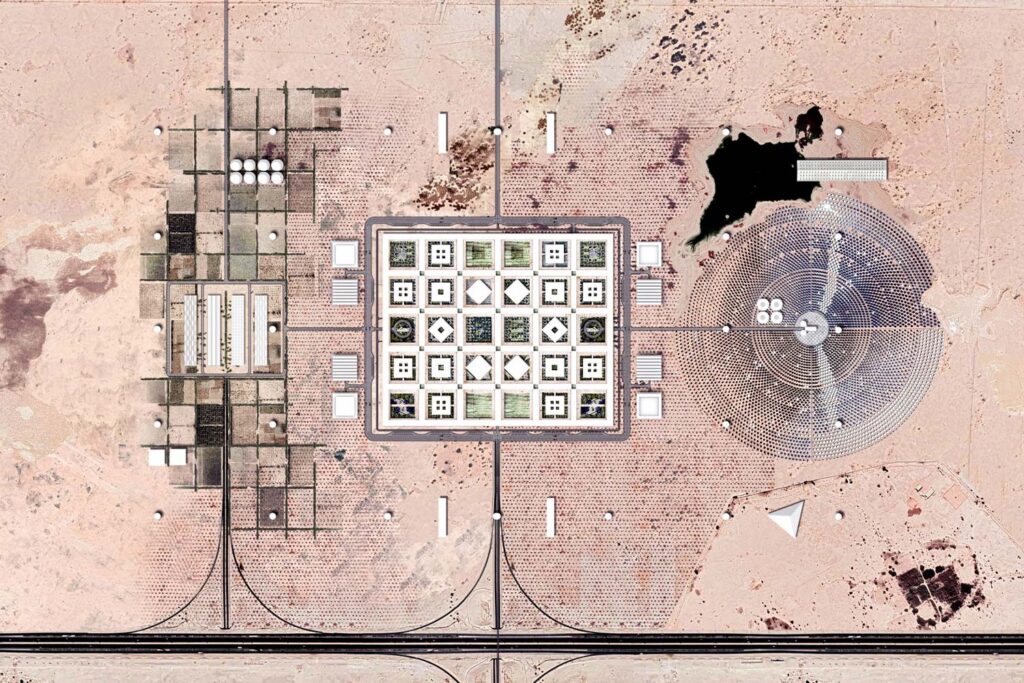

Inspired by field hospitals, which offer modular layouts that are adaptable to any given demands, the Hospital of the Future prototype would adopt a horizontal configuration in stark contrast to the traditional multi-storey stacked configuration of existing hospital facilities. This is achieved by relocating hospitals out of city centres, to areas of lower land value, where patients can benefit from being surrounded by a more rural or natural environment, while hospital facilities will have the space to expand and contract as required.

The Hospital of the Future will never be finished, it will be always growing, shrinking or morphing. The major client benefit of this approach is that the facilities within a hospital need never become obsolete – they can be perpetually updated. A fundamental enabler to this inherent adaptability is the way the prototype embraces modularity.

Each module within this “kit of parts” can function independently as well as part of the whole. Our experts identified a series of typologies of space within a hospital, isolating the structural demands of each – where equipment-heavy and vibration-sensitive spaces such as MRI or CT scanning rooms were the most structurally onerous. Many other spaces, such as bed wards, could be designed to a highly efficient level of standardisation, with plug-and-play MEP systems, water and district energy supplies, power and data, and air and medical gases.

This industrialised prefabrication approach enables rapid construction, with minimal site disruption, as well as ensuring factory grade finishes. By using a standardized formation for each new module, the hospital can expand or contract, with minimal disturbance to other hospital departments within the wider structure.

Sallyanne Lewis explains that the nature of the design also allows for all typologies of space structurally, which means that a new module can be bolted on at any time and used for any purpose.

“The nature of the design means that modules can be added on easily and the continuity of corridors and service runs is all there, you don’t have to adapt between the spaces.”

Modularity can be achieved on different scales, from components such as columns, or panels through to volumetric, or whole rooms.

Onsite prefabrication – the rise of the flying factories

To achieve this ongoing expansion and contraction as evolving needs demand, a “flying factory” is proposed, which will be a hub for on-site industrialised construction. It will be a controlled environment in which modules can be prefabricated and assembled, before these are moved to the construction site and installed.

Once construction is complete (whether fully or partially), the Flying Factory will evolve into a maintenance hub to support upkeep, adaptation of modules or ongoing expansion and contraction. Finally, at the end of the hospital’s life the Flying Factory will be a hub in which modules can be disassembled and packaged up for reuse. This capability to reuse and recycle materials on site delivers benefits both in terms of cost savings and in terms of lowering the carbon footprint of the hospital. Indeed, throughout its life, the Flying Factory adapts and pivots to be a perpetually useful facility for the hospital.

“When we were imagining this hospital, it is in the desert with unlimited space, but with relatively limited resources close by in terms of building materials,” Sallyanne Lewis says. “The client’s brief was that while we should assume it would be put in the desert, we could put them all over the world, or potentially even on the Moon. So, the challenge becomes: how do you provide all the materials, all the construction and all the resources you need to build, and how can we prefabricate as much of the building as possible?

“But what we really saw as a negative was the idea of building lots of prefabricated buildings and then transporting them across the world,” she adds. “That doesn’t feel like a good use of carbon. If you could instead create a factory close to the site that you brought all your resources to, and as much as possible you use the resources that are local to the area in which you are building your hospital, it would be much more efficient. In the desert those local resources might be stone or sand. But if you were building it in Norway, it might be timber.”

Read more on the Hospital of the Future project: How hospitals can “tread the Earth lightly” and ride out future shocks and stresses.