Pioneers in tensile and membrane structures

Buro Happold has been involved at the forefront of tensile design since 1976.

In that year, founder Ted Happold gathered together a group of engineers to tackle some of the world’s most complex engineering challenges. Collaborating with leading architects, such as Frei Otto and Mahmoud Bodo Rasch, our practice pioneered the use of lightweight membranes and tensile structures on projects of every scale around the world.

Bespoke engineering for unique tensile structures

Each tensile membrane structure is unique, and Buro Happold’s designers have the skills and creativity to experiment and create exciting solutions to conventional design problems. Using the latest technological tools, we have learnt to defy gravity, and realise the world’s most iconic tensile structures.

From the 1985 Antarctic expedition tents, to world class sport stadia, to sculptural installations, to leisure resorts in the desert, we deliver spectacular structures that delight the human spirit.

Building on a legacy of excellence

It takes fearless innovation to design iconic tensile structures, and in-depth knowledge to successfully deliver them. This rare combination of daring and diligence defines our work at BuroHappold, and was born from our earliest days as a practice.

From the blossoming of the mechanical Pink Floyd umbrellas at concerts across the USA in 1977, to the ambitious scale of the giant umbrella that enclosed the Millennium Dome, it was realising iconic tensile structures that led creative engineers from across disciplines to unite under the global umbrella of BuroHappold.

Services we offer

- Structural engineering consultancy and advice

- Tensile structure design

- Modelling and pre-construction analysis

- Lightweight membrane and material advice

Where we have used our expertise

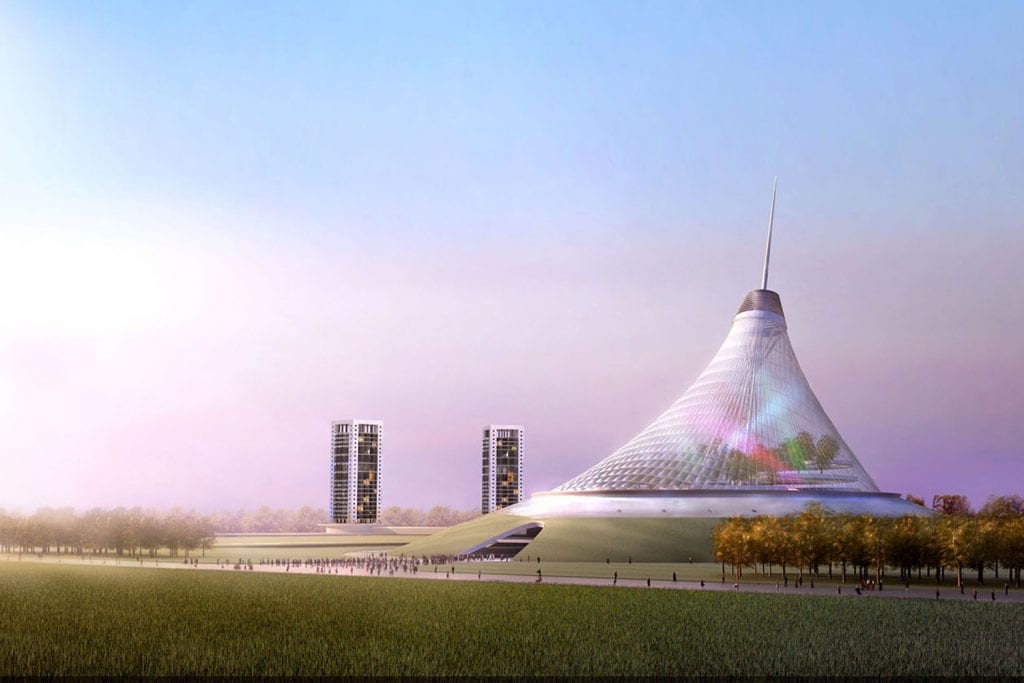

Khan Shatyr Entertainment Centre: the world’s tallest tensile structure

Astana, Kazakhstan

Towering 150m into the Astana skyline, the central mast of this iconic structure is the mainstay of the 192 steel cables that support an ultra-lightweight ETFE canopy. Each steel cable can move independently in response to changing loads imposed by wind and snow, and the transparent ETFE canopy allows daylight to flood the 100,000m² interior of the complex, while protecting visitors from temperatures that can reach +35°C in summer, and -35°C in winter.

Crystal Bridges Museum of Modern Art: high performance design

Arkansas, USA

Crystal Bridges is a masterclass in making complex engineering look effortless. Our engineers adopted bridge construction principles to realise the suspended pavilions. The roofs are a tensile cable net structure, anchored into the limestone bedrock of the landscape to stabilise the buildings.

Their geometries are based on catenary shapes created by the deflection of these cables, which realise pleasing curved forms that echo the undulations of the natural surroundings.

London 2012 Olympic Stadium: record breaking results

London, UK

The Olympic Stadium was the site of many record-breaking performances. But to ensure these records were valid, wind speeds within the Stadium had to be below 2m/s.

We engineered a tensile structure based on the concept of a bicycle wheel. The outer steel ring supported the spectator seating, and connected to an inner tension ring of 10 steel cables which formed the central opening. This structure was then covered in 112 sections of lightweight membrane to provide shelter from the elements.

Millennium Dome: a landmark entertainment venue

London, UK

Our pioneering concept for the Millennium Dome made it one of the most recognisable landmarks in the UK, and went on to support its transformation into the O2 Arena – which ranks among the most successful entertainment venues in the world.

Forming a giant umbrella over an exhibition complex, the iconic tensile structure of the roof is 320m in diameter and supported by twelve 100m tall steel masts. It is clad in 80,000m² of coated glass fibre fabric, and fitted with an additional inner membrane to achieve exceptional levels of interior comfort and acoustic performance.

Dresden Main Station: reinstating a major transport hub

Dresden, Germany

The sensitive and innovative restoration of this major station transformed a crumbling relic in a memorable transport hub.

Our real challenge came in realising a new 30,000m² roof over the delicate 19th century filigree steelwork arches of the station. Engineers from our London and Berlin offices collaborated to develop a unique, lightweight membrane of coated glass fabric that rests comfortably on the original arches, while allowing daylight to illuminate the once gloomy station interior.