Incorporating automation into hospital design

As part of our series of articles looking at Buro Happold’s Hospital of the Future project, we examine how future hospitals will be able to make the best use of automation to improve the patient and staff experience.

Automation, artificial intelligence, robotics and digital data management are playing an increasingly important role in the operational realities of our 21st century world. But how could these technological advances help to ensure future hospitals are more effective and efficient?

What can hospitals learn from other sectors to ensure staff have what they need, when they need it? Can automation deliver routine tasks to increase the amount of time staff have for patient care? Can artificial intelligence provide a safety net for staff, reducing stress and increasing retention?

These were just some of the questions posed as part of the ground-breaking conceptual Hospital of the Future project. Buro Happold worked alongside architects OMA and other collaborators, after being commissioned to explore how hospitals could be reimagined in the coming decades.

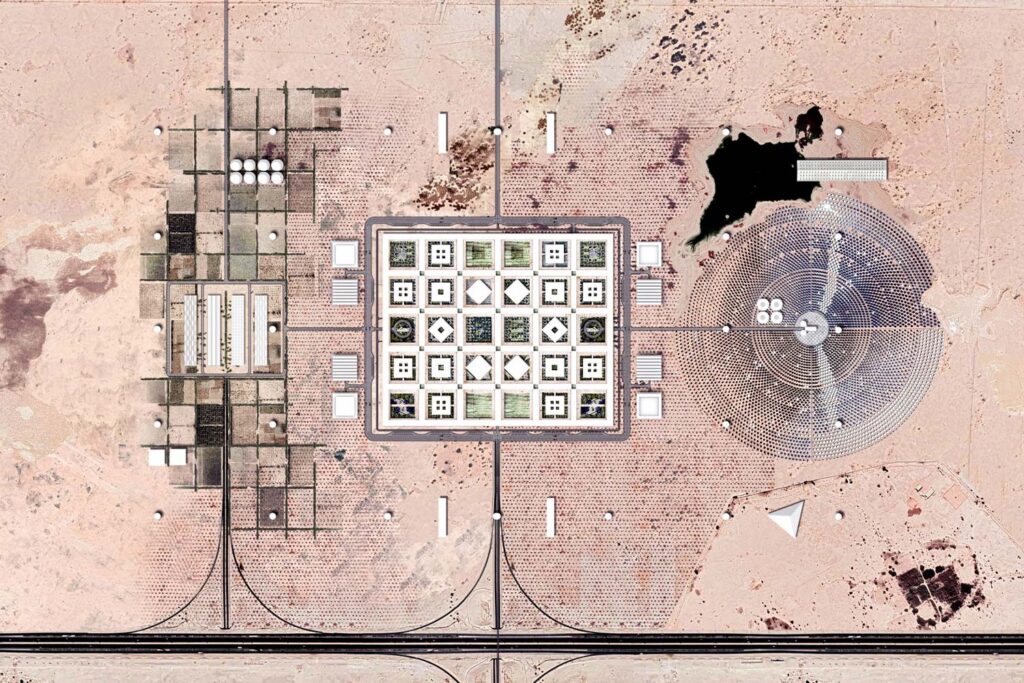

We have been working on this extensive research project in parallel with a healthcare district masterplan for a site in the Middle East. Running these workstreams together has given us the rare opportunity to explore a step change in the evolution of the hospital.

Our multidisciplinary team of experts re-examined hospitals from the first principles of design, to develop a prototype for effective future hospitals. In previous articles we have looked at how the prototype reimagines the structure of hospitals – with a horizontal orientation offering a range of benefits over the traditional stacked tower design. We looked at the importance of “treading the Earth lightly” and creating a resilient hospital capable of riding out shocks and stresses. We also examined the importance of creating an environment conducive to healing rather than just to clinically facilitate medical treatment.

But the role of automated technologies will be critical to the efficient running of the Hospital of the Future.

Building automation into hospital design

The hospital of today is reliant on manual labour and the operation of lifts for the horizontal and vertical distribution of growing volumes of goods and waste. Logistics must be carefully managed to avoid bottle necks and operational failures as well as to maintain high levels of patient experience and hygiene. In contrast, the Hospital of the Future will make use of automation to refocus staff away from manually intensive, costly and time-consuming logistical tasks.

Edward Wilkins, a senior waste management consultant at Buro Happold, says: “We asked the question of how we can make life as easy as possible for clinical staff and facilities staff, and how could that then have a knock-on impact on improving patient care.”

He says there is some inspiration to be taken from the kinds of technologies used by modern logistics or manufacturing hubs.

“The vision is for a layer sitting beneath the hospital where robots and other clever bits of technology could move around and deliver items around the complex on demand.”

Its structural design will incorporate this hidden technical layer, devoted to a faster, smarter and more resilient storage and distribution system in the horizontal plane.

Waste and goods in the Hospital of the Future will be stored and distributed via an automated, below-ground storage/distribution network. The network will connect the main hospital block with a logistics hub elsewhere on the site. The logistics hub will act as the main point on-site where trucks make deliveries and collect waste. Goods will be delivered to the hub in standardised units, which will be transferred on to the storage/distribution grid via a series of automated conveyors.

James Hobson, head of waste management consultancy at Buro Happold, adds: “We don’t want to undervalue the role of the porter. Moving products around the hospital is half of the job of the porter. The other job they do is moving patients around. One of the key things we’re doing is trying to free up their time from moving boxes to moving patients and at times comforting them, being able to talk to people, hold their hand – the sorts of things a robot can’t do. These are things that will help to create a more caring and healing setting for patients.”

Using superfast robots in hospital logistics

The storage/distribution grid will connect to the clinical areas via a series of risers/vertical shafts, with the superfast robots delivering directly to departmental stores through an ‘on demand’ service. The smaller size of these vertical shafts, when compared with traditional goods lifts, allows them to punch into the working hospital above on a much higher frequency. Each module still has a larger lift for beds and other more bulky items.

Materials can be moved directly to or from the destination without the need for horizontal transportation through the wards or departments, avoiding disruption for both staff and patients and supporting good infection control. The fact that the whole hospital is located directly above the distribution grid enables goods to be stored exactly below where they are most likely to be needed and quickly delivered upon request.

“What’s really new is that we’re integrating an automated storage/distribution system into the design. Some hospitals have tried to use automated guided vehicles (AGVs) within a hospital that was originally designed for people pushing stuff around, and that has caused problems,” Hobson says. “One of the key things we can do is to make sure the designs facilitate this technology and the possibility of it being enhanced over time.”

A large array of shapes and sizes of goods and waste containers are traditionally moved around a hospital. The proposal in the prototype is to sort these into 1m3 standardised units which should cater for the vast majority of logistical movements. Bulkier goods will travel through a separate zone in the grid.

Managing hospital data with a digital twin

With this step change in design, comes a requirement for a new approach to the operational management of the Hospital of the Future. Central to this will be a “digital twin” system that draws on the data collected in the unified data warehouse. The digital twin will have two key roles, both of which are critical in successfully managing the constant process of change that the Hospital of the Future will have to deal with.

The digital twin will play a critical role in the day-to-day operational management of the hospital. This can be this related to building performance (e.g. energy and water use management), patient tracking and guidance, goods and waste control and even for the planning of the isolation of modules within the structure where adaptation and refurbishment works are being undertaken.

Additionally, the digital twin will use data collected to analyse how successfully the prototype is performing. It will also be a vital tool in managing the capital programme on a significantly shorter cycle. It is envisaged, that the digital twin could provide a sand-box environment in which scenario testing can be created. As such it becomes a tool that capital programme managers can use to inform decisions around expansion and contraction. Read more on the Hospital of the Future project: Delivering adaptability.