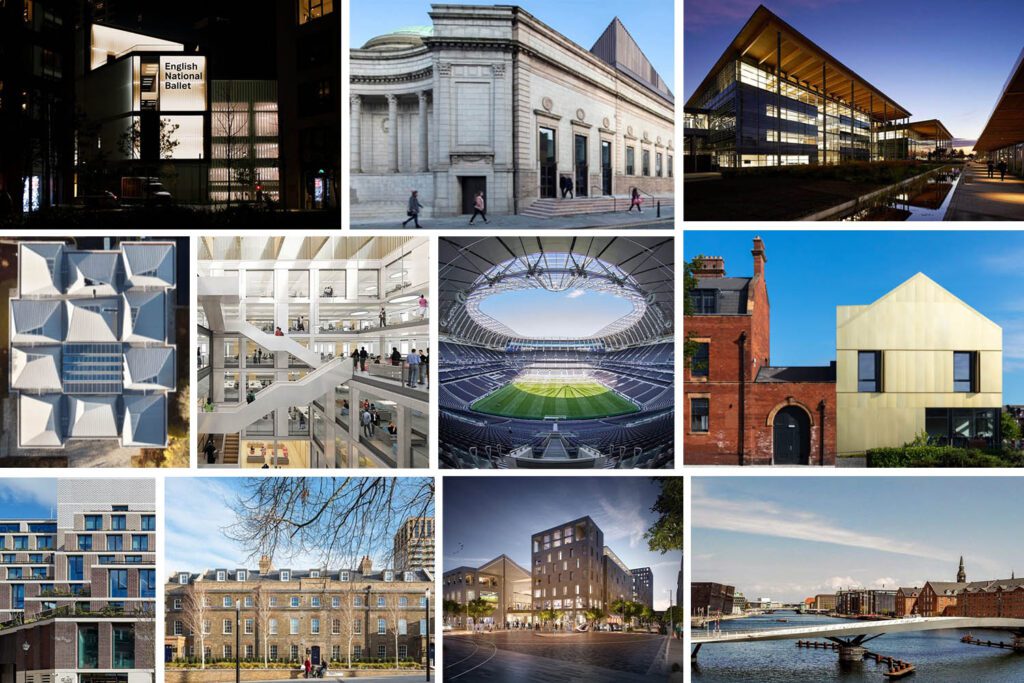

A new home for Everton: infilling Bramley-Moore Dock

Following years of research, public consultation, site surveys and engineering design, Everton Football Club took possession of Bramley-Moore Dock on 26 July 2021, with main contractor Laing O’Rourke moving in.

What would usually follow is the ground breaking ceremony, with Evertonians celebrating the start of construction for their new stadium. But what happens when there is no ground to break, and instead, there is an 1840s dock filled with water?

Ground engineering associate and job leader Jonathan Rowe discusses how Buro Happold’s ground engineering consultants made Everton’s dreams of a new stadium possible through the considered preparation and planning of the Bramley-Moore Dock infilling procedure.

‘Nil satis nisi optimum’, Everton’s Club motto, ‘Nothing but the best is good enough’ is perfectly reflected in the engineering solutions that have overcome the challenges to infill Bramley-Moore Dock.

The Grade II listed dock is approximately 10m deep and filled with 8m of water. At the bottom of the dock basin there is up to 3m of soft, blancmange like silt that has built up as a result of it being an operational dock

To dredge or not to dredge?

Typically, before infilling within a marine environment, the dock would be dredged in order to remove the soft silt. However, our team asked the question ‘Would it be possible to keep the soft silt in place and infill on top?’. Not only would this reduce the overall construction programme, but there is a huge sustainability benefit. By not having to dispose of the silt, we subsequently reduced the total import volume by 75,000m3 – enough to fill 30 Olympic-sized swimming pools.

A two phased ground investigation sampled the soft silt from boats. This allowed geotechnical laboratory tests to be undertaken that replicated the loading conditions and long-term behaviour when the infill material is placed on top. The results were promising. They showed that the magnitude of the long-term settlement could be managed with careful design considerations and remediation plans.

The next step was to select and test the infill material. In this instance, it was sand dredged from Liverpool Bay, about 25 miles north of Bramley-Moore Dock. Once again, samples were prepared in a laboratory under different conditions. This enabled predictions to be made about how the sand would perform at different depths post-compaction and final site levelling. To validate the design assumptions, Buro Happold produced a specification that defined the required properties of the material and outlined the required testing procedure to be adhered to on site for the imported material.

But what next?

Calculations were complete, and the analysis had been undertaken – surely the sand could now get pumped in? Not quite. A carefully planned sequence of works was needed first, successfully implemented through close collaboration between the marine contractor, Laing O’Rourke and Buro Happold.

1.0 Dock Raking

To minimise disruption to the piled foundations, metallic objects and obstructions within the soft silt had to be recovered. To do this, a giant rake was dragged from the back of a purpose built boat and systematically tracked across the dock, moving objects towards the east wharf. The recovered objects were then lifted ashore, documented, and appropriately disposed of.

2.0 UXO Risk Mitigation Survey

Next, a remote operated vehicle was deployed to the bottom of the dock. This was part of a geophysical UXO Risk Mitigation Survey to identify any possible unexploded ordnance to reduce the risk to the below ground construction works.

Two British anti-aircraft projectiles were identified as part of the risk mitigation survey. These were disposed of on site by the British Army and Royal Navy. This proved that the survey requirements specified by Buro Happold were appropriate to ensure the safety of the site and surrounding area.

3.0 Marine Life Protection

To protect marine life before the infilling, fish were removed and new habitats and rafts for sea birds were created. To ensure the fish did not re-enter Bramley-Moore, a silt curtain was constructed at the entrance to Sandon Half-Tide Dock to the north.

4.0 Dock Wall Protection

Remedial works to the Grade II listed dock walls (above and below the dock water level) were undertaken to preserve their condition. This was an imperative step for the proposed development as it protected the dock walls for future generations.

To protect the dock walls from structural damage during infilling, compaction and piling, tiltmeters were vertically fastened and stitched in existing penetrations to monitor lateral movement. The frequency of data collection ranged between every 15 minutes during compaction to every six hours during infilling.

“Everton FC’s Key Principles of Development state that the new stadium is to become their home and will be an environment where fans enjoy congregating and socialising. Key to this is the site’s location within the city, on the Mersey, only two miles walk from Goodison Park, rather than a characterless site on the outskirts.”

“The unlocking of this unique prime site was only possible because the Buro Happold ground engineering team solved the problem of how to fill the dock cost-effectively, sustainably, and in a viable time-frame. The Club’s desire to create a home within the historic docks required technical expertise, innovation, collaboration and persistence and I’m immensely proud of our leading role.” Andy Pottinger, Venue Design Director, Buro Happold

5.0 Temporary Dock Isolation

A temporary dock isolation structure was required in the north of Bramley-Moore Dock to retain the dock infill and to ensure the sand remained within it. The design went through many iterations of retaining solutions. The final result was a cost effective and sustainable underwater trapezoidal prism constructed from quarry obtained stone. This solution had the benefit that the temporary isolation structure could be modified to the required angle and size of the permanent structure with additional considerations added for scour and wave protection.

6.0 Dock Infill

Measuring approximately 325m long and 125m wide, Bramley-Moore Dock requires over 450,000m3 of sand to infill it, taking into consideration ongoing settlement and bulking factors.

To do this, sand dredged from Liverpool Bay is transferred via a trailer dredger, which then gets moored approximately 300m away from Bramley-Moore Dock in sufficient water depth allowing the operation of discharging the sand to not be affected by the tide.

Once moored, the trailer dredger is connected to a discharge pipeline network that is floating on the surface of the shore. The dredged material is fluidised in a hopper, and then hydraulically pumped via the pipeline over the River Mersey wall to a spreader pontoon in Bramley-Moore Dock.

Finally, the sand is hydraulically placed into the dock via the spreader pontoon. The process continues until the reclamation is above the dock water level and the remaining material is placed by a land plant.

7.0 Compaction

To ensure that the settlement of the dock infill is controlled and measurable, rapid dynamic compaction will compact the upper 6m of the infilled sand by dropping a nine tonne weight at a frequency of 60 times per minute. Following a re-profile to suit final levels, a land roller compactor completes this process, ensuring suitability for the working platform sub grade.

To validate the required relative densities have been achieved, cone penetration tests will be undertaken from platform level to the bottom of the dock basin.

8.0 Monitoring and Validation

The derived estimates of settlement magnitude, settlement rate and potential differential settlement variation are based on several parameters informed by the construction method and programme. These include dock infill placement methods, compaction and thicknesses of working platforms.

To allow continuous evaluation and obtain improved confidence in the prediction of ongoing settlement, the sinking of cased boreholes for automatic multilevel electronic extensometer installation and the installation of surface settlement monuments will be undertaken.

This is final step is vital to ensure the suitability of Bramley-Moore Dock as Everton’s new home by giving Buro Happold the ability to react to the monitoring data. As a result, a detailed construction and operation programme can be developed to establish how, when and with what influence the monitoring data feeds into the construction process. It also determines the return periods of relaying the pavements, the hard standing and the pitch surface, all of which are ground bearing.

So, what have we learnt?

It is clear that without a detailed understanding of the site, obtained by reviewing historical information, interpreting survey results, and undertaking detailed design, we could not lead innovative engineering solutions for all to see.

I have thoroughly enjoyed being part of the Buro Happold team which has led the design from concept through to construction. I am excited to see the earthworks operation, implementation and verification of the contamination remediation strategy, retaining wall construction, and the completion of the foundations. Once completed, the ground engineering team will hand over the dock to our expert structural engineers as construction commences out of the ground.