Could the next London Bridge be carbon zero?

London Bridge, which connects the City and Southwark over the River Thames, was built in the late 1960s. If we redesigned it today, could it be a carbon zero bridge?

Great strides have been made in reducing the carbon footprint of buildings, but what about bridges? Buro Happold has committed to reducing the embodied carbon intensity of all new buildings, major retrofits and infrastructure projects by 50% before 2030. Reducing the embodied carbon of infrastructure projects like bridges can be challenging, but we are determined to make this happen.

In this, the first article in a miniseries where we will explore how different bridge design choices can help minimise embodied carbon, we ask the question: can bridges become more sustainable when the largest contributor to the carbon footprint is the choice of materials?

There are three main areas to investigate when considering sustainable bridge designs:

- material efficiency

- design life – and adaptability to future use

- reuse.

What materials should we consider?

It is important to start by noting that only one of the traditional bridge building materials is carbon negative. That material is timber (and only when it is from a sustainable source); all the others will add to the carbon footprint. Now picture a bridge made of each of these materials: timber, masonry, concrete and steel. Which one achieves the longest span?

The choice of the primary structural material will depend much on the context of the site. When designing, we must ask the following questions: How long is the bridge going to be? How many supports will it have? Is it going to be divided into three, four, five, six… spans?

If – for reasons of length – we can’t use timber for the primary structure, then could we use timber for other parts of the bridge?

Sometimes computer algorithms can be used to optimise and fine tune materials and section sizes. This is done much later in the design when the details are being finalised. However, the biggest impact on sustainability will actually come at the concept design stage. Using technology to reduce carbon footprint will be addressed in a future article in this series.

Why do we need to consider how long the bridge will last?

In the UK, legislation requires a bridge to last (or have a “design life” of) 120 years! This is something that needs to be challenged, because different materials are suited to different time periods.

Think again of those steel, concrete, masonry, and timber bridges. After 120 years what will have happened to the materials?

- Steel can last over 100 years with regular maintenance

- Concrete will begin to deteriorate at about 75 years, but it can be patched

- Timber lasts around 30 years but can be extended to 50 years with maintenance

- Masonry can last a very long time (1,000 years) but, unfortunately, masonry bridges don’t span very far, so are of limited use.

In most cases, the need for a 120-year design life forces us to use steel or concrete. (The concept of 120-year design life also makes some pretty big assumptions, which we’ll explore in a future article.)

How can a bridge be adaptable for use both now and in the future?

For a bridge to be adaptable, we must research the usage and purpose of the bridge over its lifetime during the early design stages. We ask the following questions:

- Will the usage of the bridge increase or decrease?

- Will the way people use the bridge change?

- Will the percentage of bridge users walking or cycling change?

- Will the purpose of the bridge change?

To help us make decisions about the bridge’s design to ensure it remains more adaptable, we need to do some research. We need to look closely at the demographics, trends and developments in the area surrounding the bridge over the past 10, 20, 50 or 100 years. This can influence our thinking: for example, could the bridge be designed to be widened or narrowed for future use?

When and where can we reuse components and materials?

Another question to ask when considering adaptability is what could be left for reuse in the future?

When building a new, more sustainable bridge on the site of a former one, people ask if it’s possible to reuse components of the bridge. We consider elements such as piers, abutments and foundations. We also ask ourselves if it is possible to reuse some of the recovered materials.

Flip this around and we could also start designing elements in a way that they could be reused in future bridges.

So, could the next London Bridge be carbon zero?

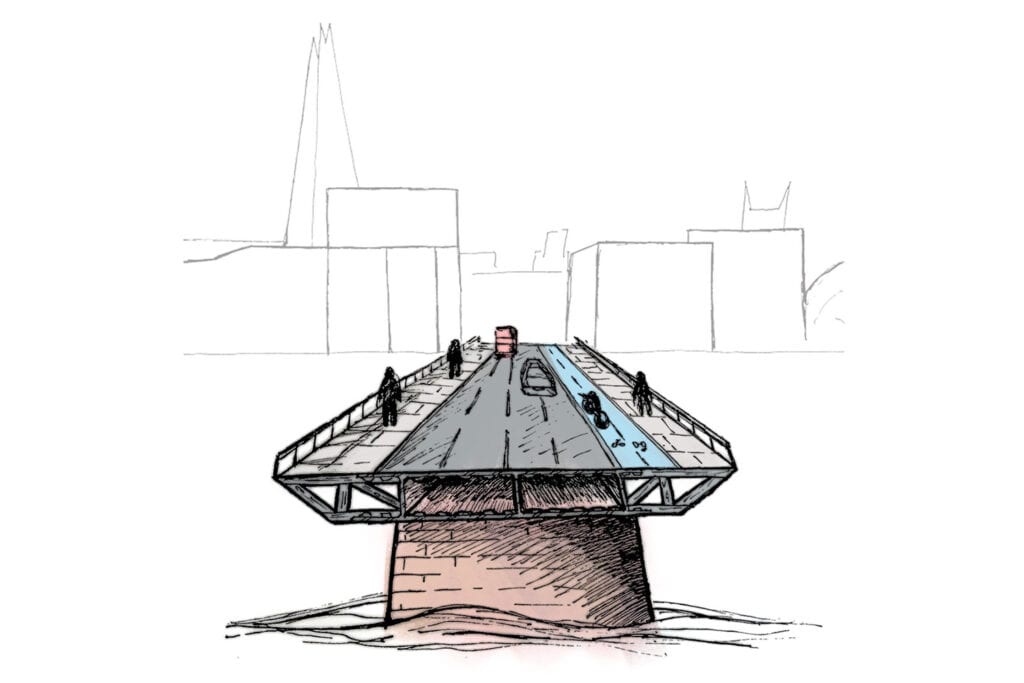

To cross the Thames, the total length of the bridge would need to be about 270 metres. The current bridge has three spans, the longest of which is 100 metres. If we were to reuse the piers of the current bridge, this would remove the carbon footprint involved in creating new foundations. But it would also mean we’d need to span exactly the same distances as the current bridge.

To help us consider the width of the new carbon zero bridge, we looked at the current statistics for usage of London Bridge. The Department for Transport reports that the number of motor vehicles using the bridge daily has dropped from 37,500 in 2000 to 19,500 in 2019. This decline in the number of motor vehicles has also been noticed on other nearby bridges. At the same time, the number of cyclists using the bridge every day is up from 2,600 in 2000 to 7,200 in 2019.

A new carbon zero London Bridge will need to meet the requirements for today, but if the current trends continue, would it need to meet these during its entire lifetime? From the statistics available we believe it would not.

A primary structure could be built to meet the 120-years design life for a bridge. It could be designed with a width appropriate to the lower expected usage rates for 50 years’ time. But what about today? Why not use timber extensions to provide extra width and space for the next 30 years?

Switching a third of the bridge from steel to timber could save 2,200 tonnes of steel, which is equivalent to 5,500 tonnes of carbon. The timber carbon offset could reduce the carbon footprint by a further 2,900 tonnes. These are based on rough cradle to cradle calculations, but it does demonstrate that this could reduce the overall carbon footprint by almost 10,000 tonnes. To put this into context, you might have an annual carbon footprint of 4 to 5 tonnes.

Doing this would benefit both the bridge and the environment. It would reduce the quantum of steel and the carbon footprint, as well as creating a more appropriate and adaptable space for future use.

We recognise that timber could not fulfil the role as the primary structure in this case. Instead, we would use timber wherever possible to provide secondary, and tertiary structures which would help reduce the overall carbon footprint.

More coming soon…

The carbon footprint of a new London Bridge will depend on many design choices, not just materials. We’ll explore these in future articles in this series, so stay with us as we continue to develop the bridge’s design.

In the meantime, what materials would you choose if you were redesigning London Bridge, and why?

Sources:

- Global Sustainability Report: https://www.burohappold.com/publications/global-sustainability-report-2020

- Department of Transport figures: https://roadtraffic.dft.gov.uk/manualcountpoints/38269