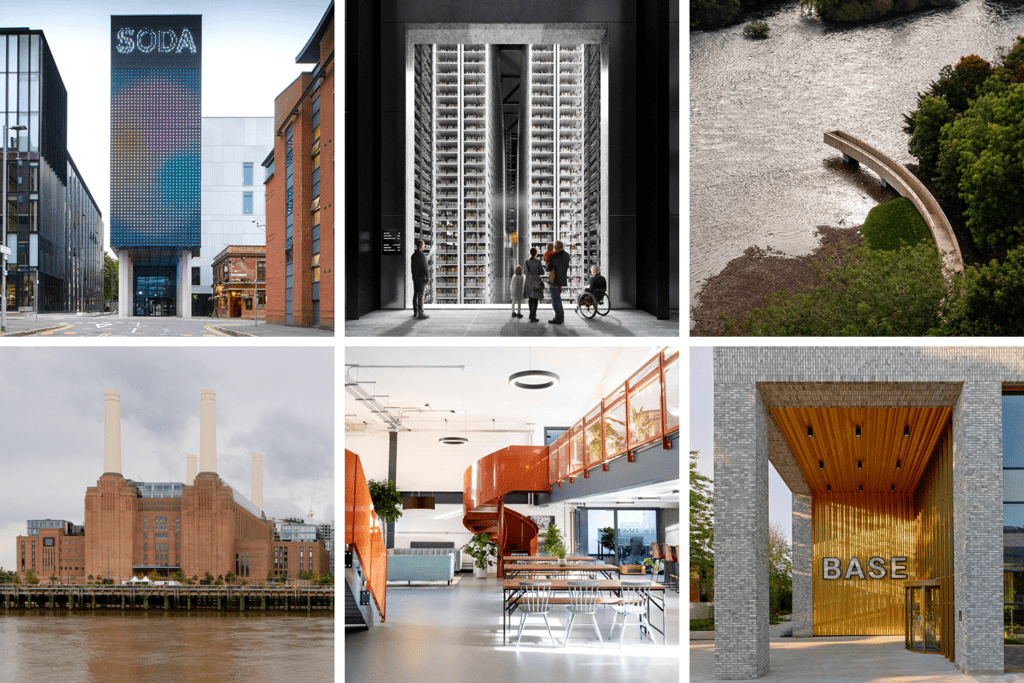

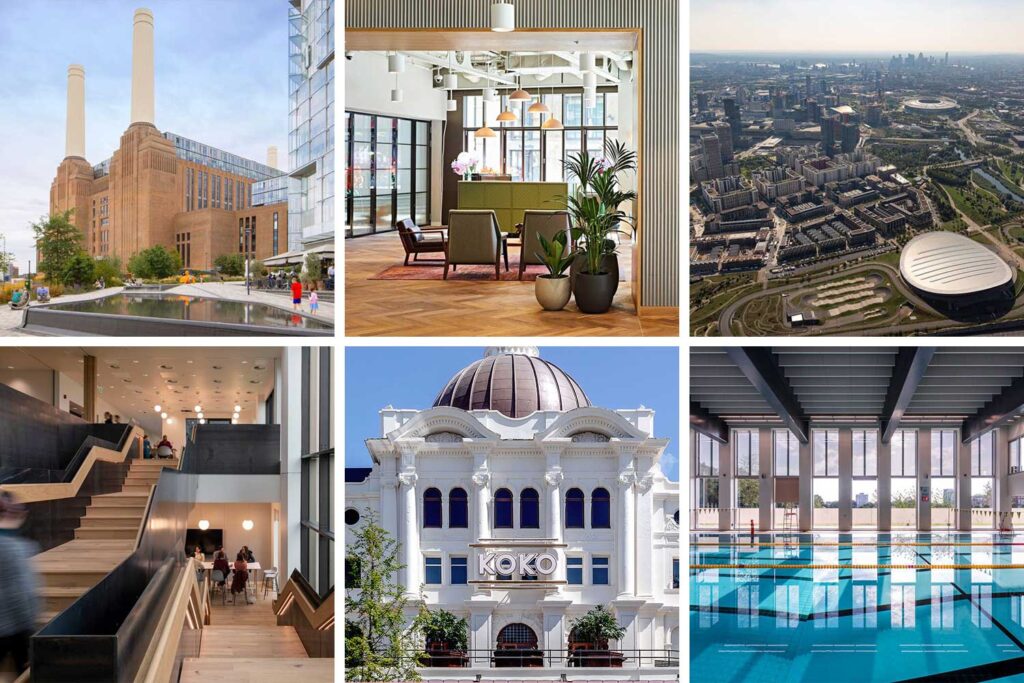

Six spectacular projects shortlisted for IStructE Awards

Buro Happold projects from across the world have been recognised for their structural engineering excellence

For over 50 years, the IStructE Awards have celebrated outstanding engineering achievements across the globe. This year, Buro Happold is honoured to have six projects shortlisted for the Awards that reflect the diversity of our work in areas ranging from Construction Innovation to Structures in Extreme Conditions.

As a practice, we strive to push the boundaries of design and engineering so that we can create a built environment that is beautiful, functional and sustainable for people and planet. Our in-house experts look to the latest technologies, adapting and developing software that enables us to re-imagine our world and deliver the seemingly impossible. Whether that is using AI to subvert the skyscraper, or harnessing data to inform our work, we look to deliver projects that set new standards in design, and we are extremely proud that this ingenuity and innovation has been recognised.

Winners will be announced at the Awards Ceremony on Friday 15th November, but in the meantime here is a round-up of the six projects that have been shortlisted – and the reasons why they made the cut.

Morpheus, Macau, China

Category: Construction (Innovation)

Sculptural in form, the striking steel and glass lattice shell that encases Morpheus is one of the most visually dramatic large-scale steelworks of its kind. Our structural engineers undertook detailed analysis and imaginative engineering design to realise this unique exposed exoskeleton, developing a complex mesh structure that gives the tower the dynamism required to withstand the region’s typhoon climate.

Our team developed bespoke software that enabled us to process the huge number of models required and, critically, the 3D visualisations of every structural connection. This unique methodology led us to use software in highly original ways, manipulating its capabilities to provide true innovation and excellence in design.

Xiqu Centre, West Kowloon Cultural District, Hong Kong

Category: Construction (Innovation)

Created to provide the first permanent home for Chinese opera in Hong Kong, the Xiqu Centre is the first of 17 arts and cultural venues located in the newly formed West Kowloon Cultural District. The sinuous curves of its iconic facade resemble curtains, drawing apart to reveal an inviting cultural sanctuary that blends theatre, art and the public realm.

Seven teams from BuroHappold have been involved in creating this striking landmark – providing everything from facade to fire engineering. Our experts collaborated with the wider design team to deliver the entire project in a digital BIM environment. This enabled us to resolve and coordinate every aspect of the building design to deliver dynamic spaces that can adapt to host a range of international arts programmes.

Hong Kong Port Passenger Clearance Building, Hong Kong – Zhuhai – Macao Bridge, Hong Kong

Category: Construction (Innovation)

The undulating form of the Passenger Clearance Building is the centrepiece for the Hong Kong – Zhuhai – Macao Bridge, which is itself one of the largest mega-engineering projects in the world. Our structural engineers optimised the wave-like steelwork of the roof, so that it is beautiful in appearance but also imbued with the strength and flexibility required to endure the region’s typhoons, monsoon rains, marine environment and high humidity.

We also developed a modular design for the roof that was able to realise the fluid, freeform geometry, while also simplifying the construction process to reduce cost and time. Overall, our structural, facade and sustainability expertise realised an exceptional travel facility that combines aesthetic grace with high performance systems that ensure an unrivalled passenger experience.

Tottenham Hotspur FC, London, UK

Category: Long Span Structures

Built on the footprint of the legendary White Hart Lane football ground, and constructed while the venue remained in operation, this UEFA/FIFA compliant stadium is designed to deliver an incredible experience for football fans and perform as a multipurpose sports and entertainment arena.

Our pioneering long span design enables the football pitch to split three ways and slide beneath the south stand of seating, transforming the stadium from a bespoke football ground into a flexible venue that can also support NFL games, corporate events and concerts.

Airbus Wing Integration Centre, Bristol, UK

Category: Structures in Extreme Conditions

Our brief for this flagship aviation facility was succinct, but challenging – we needed to design a state of the art ‘strong wall’ and ‘strong floor’ that had the capacity to withstand the most rigorous testing of modern aircraft wings. We developed a bespoke design to realise a strong wall and strong floor of the highest execution class – usually reserved for buildings such as nuclear testing plants.

We conceived a unique modular design for the strong wall, which allows it to be configured in multiple layouts to enable simultaneous testing of two A320 family wings, or single testing of a larger aircraft wing. Both the strong wall and floor are manufactured to extremely tight tolerances to provide a seamless testing arrangement for Airbus, and will be able to withstand half a billion cycles of wing loading without failure.

Northern Spire, Sunderland, UK

Category: Vehicle Bridges

This elegant, cable stayed bridge is the first new crossing of the River Wear for 45 years. Spanning 340m in length, it will carry two lands of traffic in each direction, together with dedicated cycle ways and footpaths to create a much-needed link that will stimulate regeneration in the area.

A vital part of our work involved developing an innovative construction method that saw the incremental deck launch and roll up of the bridge’s main pylon. This approach allowed off-site manufacture of the bridge steelwork, which minimised the amount of work carried out on site – improving the safety of people working on site, and also reducing the potential for delays on the project.