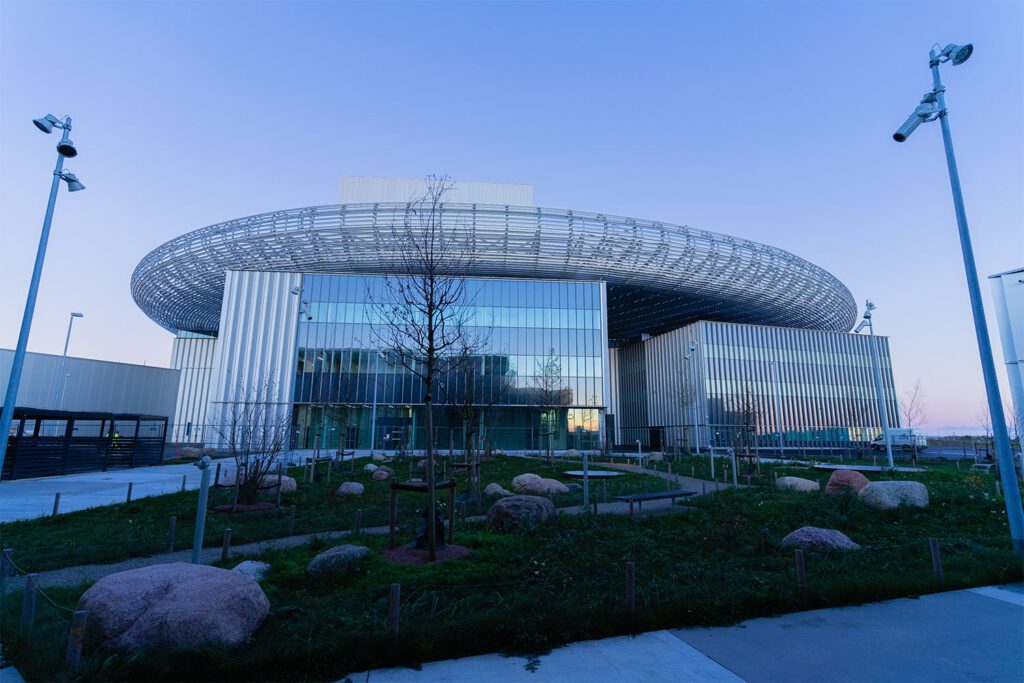

European Spallation Source (ESS): Target Building Roof

Lund, Sweden

Project details

Client

European Spallation Source

Architect

Henning Larsen, COBE

Services provided by Buro Happold

The opening of the ESS will herald a new era of materials research. The facility will include the most powerful linear accelerator ever built and make use of the latest spallation technology, enabling researchers to produce neutron beams that are up to 100 times brighter than today’s standard, making it the leading neutron spallation’s source in the world.

In spallation sources, protons that are accelerated to near the speed of light hit a target, from which the neutrons needed for research are released. Neutron research is used to study materials at an atomic level and drive innovation in fields such as energy, medicine, engineering, chemistry, and the environment.

The two key elements of the spallation process at the ESS are the 600 metre long linear proton accelerator and a 4-tonne tungsten target wheel, working in tandem to generate the neutrons that will provide researchers with precise information about the studied materials’ structure and dynamics. Buro Happold was commissioned to design an extraordinarily strong yet lightweight large steel-framed roof structure to cover the target building and associated Experimental Halls that can withstand both extreme winter weather and seismic activity. The dramatic roof will be the focal point and iconic visual identity for the ESS.

Challenge

In accordance with the regulatory framework for spallation facilities like the ESS, it is of paramount importance to ensure that the steel roof structure is engineered to withstand extreme wind, snow and even earthquakes over a period much longer than the anticipated design life of the building. Moreover the design of the roof needed to allow for the changing needs of the research facility.

The sheer size and loading applied to the roof, covering an area of 200×150 metres, were the first set of challenges for our engineering design team. The profile of the roof includes cantilevers up to 35 meters beyond the perimeter of the building. For this reason, the roof has been designed to withstand, increasing environmental factors such as high winds and the heavy build-up of snow.

Solution

In order to overcome these issues, our team developed a semi-porous ribbed roof facade system that reduces the magnitude of environmental loading. The extra benefit of this approach allowed us to reduce the quantity and thus the cost of the steelwork. In close collaboration with the architectural team and facade specialists, we developed a design for the external facade of the cantilevered roof to incorporate aluminium fins. We used parametric tools to optimise the shape and dimensions of the panels, minimising the number of bespoke elements. Nesting on the rib steelwork, the fins are specially shaped to allow wind to pass through them and snow to fall to the ground without compromising the integrity of the cantilevered roof. Working in collaboration with specialist testing companies, the effects of wind and snow were verified with scale model testing and computational fluid dynamic (CFD) analysis. Our team also used parametric tools that aided both the design and modelling processes. These enabled more efficient calculations, ensured error-proof modelling and resulted in a better final product for our client.

Further adding value, we considered the construction process during the early stages of the project to ensure efficiency. Solutions include standardising steelwork elements despite the complex geometry of the roof and specifying prefabricated façade fin-panels, allowing them to be quickly and safely installed on-site. Demonstrating our experience with working on complex structures, a specialist parametric modelling tool was produced to significantly reduce the number of different types of facade panels required for the cantilevered roof. This resulted in great efficiencies in terms of fabrication and installation from a sustainability perspective, while the amount of material wastage in this system was significantly reduced.

Value

The European Spallation Source facility is destined to further our understanding of the universe, providing insight that was previously not possible to achieve. Our contribution to the project entailed engineering innovation and careful planning to ensure the ESS Target Building Roof will be built strong enough to shield the world’s most powerful neutron research facility from a variety of extreme environmental factors, yet remain flexible in design to accommodate the future of particle science.